Introduction:

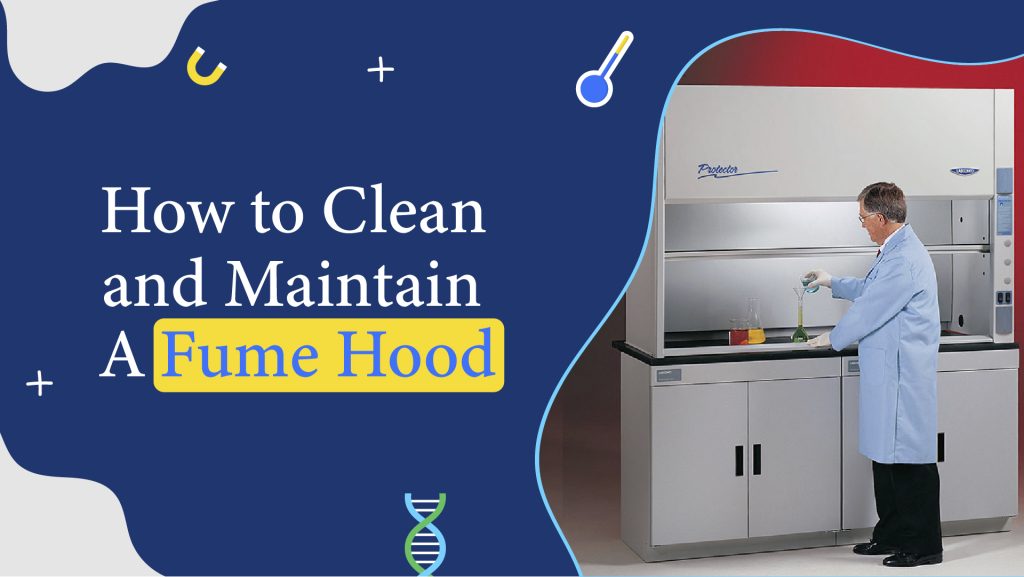

How to Clean and Maintain a Fume Hood are essential components in laboratories and industrial settings, providing a controlled environment to handle hazardous substances. Proper cleaning and maintenance of these units are crucial to ensure a safe working environment and maintain optimal performance. In this article, we will explore a detailed guide on how to clean and maintain a fume hood, including a fume hood cleaning checklist, maintenance schedule, inspection routines, testing procedures, and best practices.

Fume Hood Cleaning Checklist:

Clearing Workspace:

– Remove all materials from the fume hood to access every surface.

– Check for any spills or residues on the work surface.

Cleaning Surfaces:

– Use a mild detergent or a fume hood-specific cleaner to wipe down all surfaces.

– Pay special attention to seams, joints, and corners where contaminants may accumulate.

– Rinse thoroughly with deionized water to remove any cleaning residue.

Cleaning Sashes and Windows:

– Clean transparent surfaces with a glass cleaner for optimal visibility.

– Ensure the sashes move freely and lubricate hinges if necessary.

Inspecting Filters:

– Replace or clean filters according to the manufacturer’s guidelines.

– Inspect for any damage or signs of wear.

Checking Airflow:

– Verify that airflow indicators are functioning correctly.

– Use smoke tubes or other airflow visualization methods to ensure proper containment.

How Often Should You Clean Your Fume Hood?

Routine Cleaning:

– Perform daily cleaning for workspaces with high chemical usage.

– Conduct a thorough cleaning at least once a week.

Filter Maintenance:

– Follow the manufacturer’s recommendations for filter replacement.

– Regularly inspect filters for any signs of saturation or damage.

How to Clean and Maintain a Fume Hood Maintenance Checklist:

Scheduled Inspections:

– Establish a routine inspection schedule, typically quarterly.

– Document any issues and address them promptly.

Testing Alarms and Sensors:

– Test audible and visual alarms to ensure they activate appropriately.

– Check gas and airflow sensors for accuracy.

How Often Should You Inspect Your Fume Hood?

Regular Inspections:

– Perform monthly inspections to identify any potential issues.

– Schedule a professional inspection annually for a comprehensive assessment.

How to Test Your Fume Hood:

Smoke Tests:

– Conduct regular smoke tests to visualize airflow patterns.

– Ensure that smoke is effectively contained within the hood.

Face Velocity Measurements:

– Use an anemometer to measure face velocity.

– Compare measurements with recommended levels to confirm proper airflow.

Follow Best Practices:

Adhere to Standard Operating Procedures:

– Train personnel to follow established protocols.

– Encourage the use of secondary containment devices for added safety.

What If Your Fume Hood Is Broken?

Immediate Action:

– If a malfunction is detected, cease operations in the affected hood.

– Clearly label the unit as out of order and report the issue to maintenance.

Conclusion:

Maintaining and cleaning a fume hood is critical for the safety of laboratory personnel and the integrity of experiments. By following the guidelines outlined in this comprehensive guide, laboratories can create a secure working environment, extend the lifespan of their fume hoods, and ensure the efficient containment of hazardous materials. Always refer to the manufacturer’s instructions and consult with professionals when in doubt about the maintenance and repair of fume hoods.